Zaawansowana linia rur izolowanych pianką natryskową do gorącej / schłodzonej wody / ropy / rurociągu materiałów chemicznych

Opis produktu

Sztywna poliuretanowa rura izolacyjna Huashida, natryskiwana, z polietylenowym uzwojeniem, prefabrykowana, bezpośrednio zakopana, składa się ze stalowej rury roboczej, natryskowej warstwy izolacyjnej z sztywnej pianki poliuretanowej i polietylenowej rury ochronnej.

Linia wykorzystuje ciągły proces produkcji natryskowej. Charakteryzuje się wysokim stopniem automatyzacji, szybką wydajnością produkcji, oszczędnością surowców, zwiększonym spienianiem i stopniem zamkniętych komórek, zmniejszonym wskaźnikiem absorpcji wody oraz formowaniem trzy w jednym, co sprawia, że jej wydajność jest bardziej niezawodna. Produkty niskoemisyjne i przyjazne dla środowiska mają wysokie korzyści ekonomiczne i społeczne.

Linia produkcyjna składa się z trzech głównych części:

√ Piaskarka do rur stalowych

√ Linia produkcyjna do natrysku poliuretanu

√ Linia produkcyjna do nawijania osłony zewnętrznej PE

Scenariusz zastosowania:

Stosowana głównie do produkcji rur termoizolacyjnych do ogrzewania, chłodzenia, ropy naftowej, chemii i innych dziedzin.

Parametry produktu

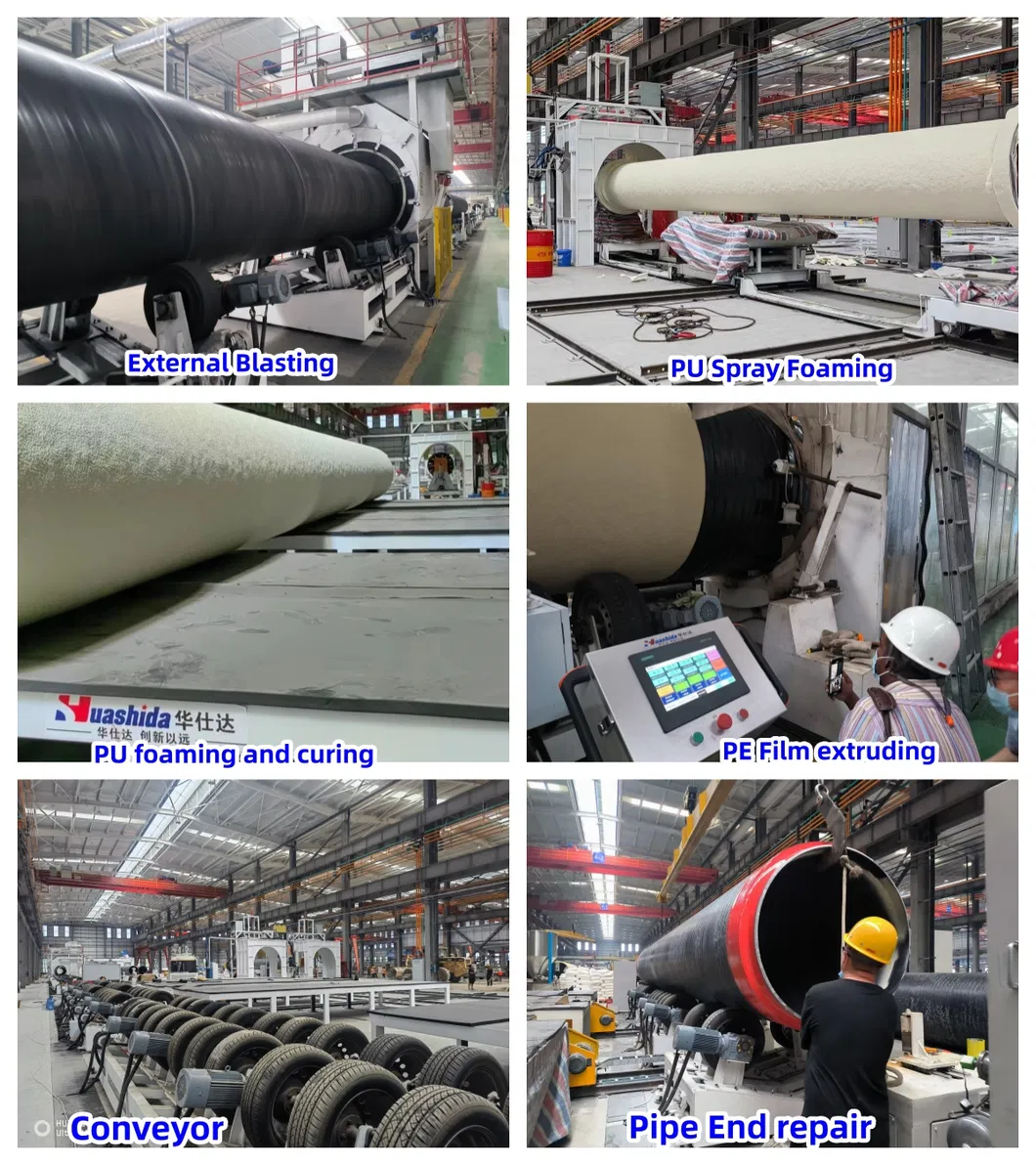

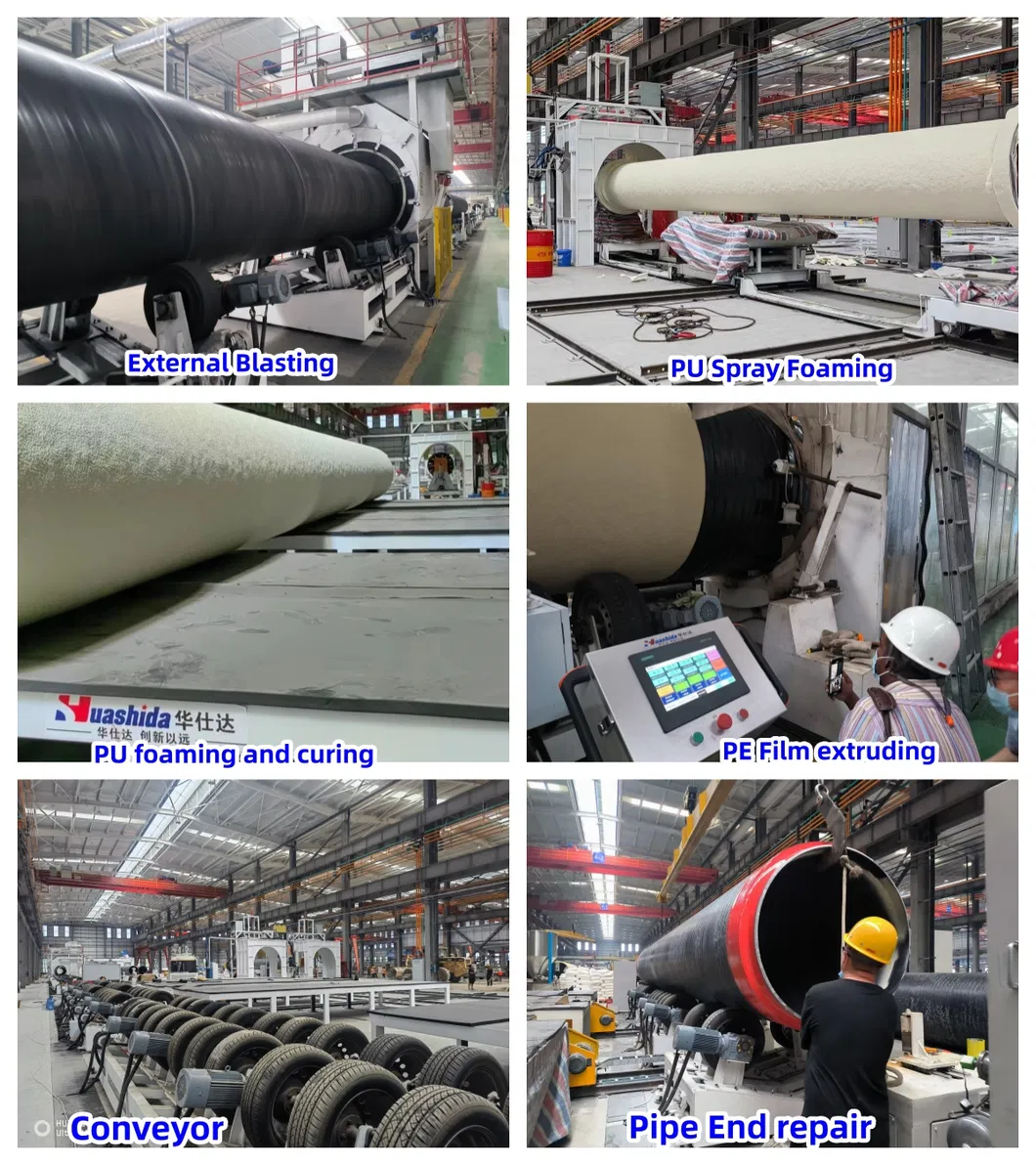

Etapy produkcji:

1. Zewnętrzne piaskowanie w celu usunięcia rdzy ze stalowej rury

2. Rura stalowa przenoszona do linii transportowej natryskowej za pomocą wózka transportowego

3. Wstępne podgrzewanie rury

4. Natrysk pianki poliuretanowej

5. Rura transportowana na platformę magazynową za pomocą wózka podnoszącego

6. Nawijanie osłony PE

7. Chłodzenie wodą

8. Cięcie połączeń

9. Kontrola gotowej rury

10. Naprawa końców rur

11. Kodowanie natryskowe i pakowanie

Parametr linii produkcyjnej:

1. Zakres rur stalowych: 206mm-1820mm

2. Wydajność przetwarzania:≤250m2/h

3. Klasa czyszczenia: Sa2.5

4. Użyty materiał: ISO (izocyjanian), POLY (premiks poliolu polieterowego), PE

5. Główne wyposażenie: Linia produkcyjna do piaskowania i usuwania rdzy, Linia produkcyjna do natrysku poliuretanu, Linia produkcyjna do nawijania PE.

Wyposażenie Pokaż:

Parametry techniczne

| Średnica rury stalowej (mm) |

Grubość izolacji (mm) |

Średnica osłony zewnętrznej (mm) |

Minimalna grubość ścianki osłony zewnętrznej (mm) |

| 500 |

30-60 |

580-640 |

5.6 |

| 630 |

30-60 |

710-772 |

6.6 |

| 710 |

30-60 |

790-850 |

7.2 |

| 800 |

30-60 |

885-950 |

7.9 |

| 900 |

30-60 |

980-1054 |

8.7 |

| 1000 |

30-60 |

1090-1155 |

9.4 |

| 1100 |

30-60 |

1190-1250 |

10.2 |

| 1200 |

40-100 |

1316-1436 |

11 |

| 1400 |

50-100 |

1538-1638 |

12.5 |

| 1500 |

50-100 |

1638-1738 |

12.5 |

Nasze zalety

1. Nagrodzony pierwszym (zestawem) sprzętem technicznym w prowincji Shandong

2. Raport z oceny standaryzacji osiągnięć naukowych i technologicznych w mieście Qingdao

3. Posiadanie wielu patentów krajowych

4. Inteligencja, automatyzacja i redukcja pracy ręcznej

5. Wydajny i energooszczędny, o niskich kosztach produkcji

6. Stabilny i niezawodny, z wysoką wydajnością gotowych produktów i minimalną ilością odpadów

Międzynarodowa wystawa handlowa

Certyfikaty

Nasz zespół

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!